Surgical Sutures

Surgical Sutures are indispensable for closing wounds, having the capacity to exert larger force than tissue adhesives and speeding up the natural healing process. There are many surgical suture materials which have been adopted for this purpose – such as degradable and nondegradable plastics, biologically derived proteins, and metals – but their performance has been limited by their stiffness. Conventional suture materials can cause discomfort, inflammation and impaired healing, among other post-surgical complications.

In an effort to remedy this problem, researchers from Montreal have developed innovative tough gel sheathed (TGS) surgical sutures inspired by the human tendon.

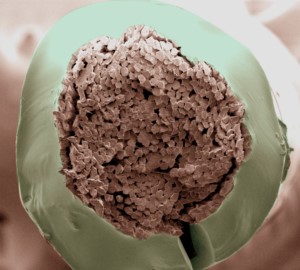

These next-generation sutures contain a slippery, yet tough gel envelop, imitating the structure of soft connective tissues. In putting the tough gel sheathed (TGS) surgical sutures to the test, the researchers found that the nearly frictionless gel surface mitigated the damage typically caused by traditional sutures.

Conventional surgical sutures have been around for centuries and are used to hold wounds together until the healing process is complete. But they are far from ideal for tissue repair. The rough fibers can slice and damage already fragile tissues, leading to discomfort and post-surgery complications.

According to the researchers, part of the problem with conventional sutures is the mismatch between our soft tissues and the rigidity of sutures which rub against contacting tissue. McGill University and the INRS Énergie Matériaux Télécommunications Research Centre team approached this problem by developing a new technology which mimics the mechanics of tendons.

Inspired by the Human Tendons

To tackle the problem, the team developed a new technology that mimics the mechanics of tendons. “Our design is inspired by the human body, the endotenon sheath, which is both tough and strong due to its double-network structure.

It binds collagen fibers together while its elastin network strengthens it,” says lead author Zhenwei Ma, a PhD student under the supervision of Assistant Professor Jianyu Li at McGill University.

The endotenon sheath forms a slippery surface to reduce friction with surrounding tissue and also delivers materials for tissue repair in a tendon injury, comprising cells and blood vessels and mass transport and tendon repair.

Tough gel sheathed (TGS) surgical sutures can be engineered to provide personalized medicine based on a patient’s needs, say the researchers.

Next Generation Suture Materials

The McGill University sutures contain a popular commercial braided suture within a gel envelope mimicking this sheath. The tough gel sheathed (TGS) surgical sutures can be fabricated up to 15cm long and can be freeze-dried for long-term storage.

Using first a porcine skin and then a rat model, the researchers demonstrated that they can be used for standard surgical stitches and knots and are effective for wound closure without causing infection.

The tough gel sheathed (TGS) surgical sutures – in another parallel with endotenon sheaths – can also be designed to provide personalised wound treatment.

Personalized Wound Treatment

The researchers demonstrated this principle by loading the sutures with an antibacterial compound, pH sensing microparticles, drugs and fluorescent nanoparticles for anti-infection, wound bed monitoring, drug delivery and bioimaging applications.

“This technology provides a versatile tool for advanced wound management. We believe it could be used to deliver drugs, prevent infections, or even monitor wounds with near-infrared imaging,” says Li of the Department of Mechanical Engineering.

“The ability to monitor wounds locally and adjust the treatment strategy for better healing is an exciting direction to explore,” says Li, who is also a Canada Research Chair in Biomaterials and Musculoskeletal Health.

Primary References:

1. McGill University

2. Bioinspired tough gel sheath for robust and versatile surface functionalization. Zhenwei Ma et. al. Science Advances, 2021; 7 (15): eabc3012 DOI: 10.1126/sciadv.abc3012

Post time: Apr-02-2022